An introduction to reloading - Part 2

"Once is not enough." A well-known slogan promoting the idea of bringing used items back to life is also a perfect motto for a handloader. Recycle, restore, reload

Reloading- the main idea

The term "reloading ammo" goes without saying. Fire your round, take the empty shell, clean it, restore to its original shape, change the primer, put in a new powder load and seat the bullet. Done.

You could stay at this basic level of a pure joy of doing it yourself. It does not have to be special in any particular way nor achieved by a long developing phase. Just a safe load poured in the case, the bullet sat at the right depth and there it is: a cartridge made by you, not for you.

You could also take a deep dive in the topic of how it actually works and what you can do in order for it to work better for you. And that is because the handloader himself is responsible for every decision regarding any parameter of the cartridge. He or she develops a unique cartridge composition according to which it is to be built: the type and weight of the bullet used, the seating depth, the type of powder and its load, the type of primer, and finally the method of preparing the cartridge case for re-use.

He or she can finally approach the selection of components very critically, determine - within acceptable standards – the overall cartridge length or select the force holding the bullet in place. And then – any reloading phase can be improved almost infinitely, by super-precise weighing, measuring, only partial brass sizing, etc., One will quickly realize there’s always a level deeper into the madness.

At this point, it should be noted that this is not the purpose of my articles by any means. Bragging about what and (especially) how can be achieved by handloading could be downright discouraging and counterproductive.

Instead, as a kind of introduction to the series of articles devoted to reloading, I would like to describe the particular stages of creating your own recipe in general, without getting in too deep. So that by understanding the purpose of the following steps and their importance for the whole process, you do not get lost in it.

May my contribution to Norma Academy be a primary school rather than a real university? Let it be a help to decide whether handloading makes sense in your particular case, especially since it is an engaging activity and requires the purchase of tools, which are usually not cheap even in basic versions.

The four most important steps in reloading

Reloading is based on four basic phases: conceptualization, shell preparation, powder weighing and bullet seating. Each of them contains many activities, and the care with which they are performed can have a direct impact on the final success or failure.

However, before a handloader sits down in his workshop, he or she should always ask two key question: WHAT do I want to achieve? And, even more importantly, HOW DO I reach my goal SAFELY?

Reloading is a completely safe activity only if the applicable rules are followed. You must always remember that carelessness, nonchalance or thoughtless experimentation can lead to disability or even death of the shooter! Therefore, it is particularly important to take the first steps under the guidance of an experienced colleague, preceded by reading the available textbooks.

Step 1 in reloading: the concept

That is undoubtedly the most important stage. This is the time to define the purpose for which the cartridges will be used: the game that will be the object of the hunt and the conditions in which it will take place or - or the nature of the shooting discipline in the case of sport shooters. What projectile will match the requirements the best? How fast should it go past the barrel muzzle?

The next step will be to choose the powder that the manufacturer's manual will indicate as appropriate for this bullet and caliber. Manuals are traditionally provided in paper form, but more and more often many tables can also be found in pdf versions and apps such as NormaBallistics. The manual always tells with what load to start with and what must not be exceed. Please note that only a manufacturer’s manual may be considered as a fully reliable source of information!

The choice of primers is simple - their type clearly defines the application: small pistol and large pistol, small rifle and large rifle. In addition, the word "magnum" may appear next to all types - specifying the application. This is also the right time to check whether all necessary tools are available, in particular dies for a given caliber.

Upon completion of the first stage, the handloader will have the bullet, powder and primer selected and load ranges defined.

It is worth keeping a reloading diary in a notebook (with tested and finally selected recipes, as well as shooting results: copies of targets and records of muzzle velocity values read from the chronometer.) Good notes can be invaluable in the future.

Step 2 in reloading: case preparation

Reloading - as the name suggests - assumes the reuse of shells left after shooting. However, it is worth noting that for the first round, it is good to opt for a new shell, which will be used many times in the future.

Cases that stay in the reloading rotation will have the fired primers removed, and then go through cleaning in a special tumbler or ultrasonic bath. Then they will be sorted, which is a very important step. It is primarily aimed at eliminating those that are not suitable for reuse: because of cracks (usually appearing on the neck or shoulders) or narrowing in the lower part (visible or palpable only from the inside) or other defects. These blemishes can result in backflow of gases or a case separation, resulting in its fragment being stuck in the chamber.

Another vital purpose of sorting is to select a possibly homogeneous group of shells (weight and volume), which is an important first step to getting the resulting cartridges as uniform as possible.

Once in a while, it is necessary to shorten the brass to the nominal length (according to the manual) with a special trimmer.

The next phase is to cover the shell with lubricant in order to avoid jamming in the die during sizing. The substance can be applied by using a sprayer (manufacturers offer ready-made bottles with an atomizer), by rolling the brass on a greased pad or spreading it with your fingers. The latter method, although the least effective, has the advantage of allowing the case to be checked again - sometimes it happens that a minor defect escapes attention during sorting.

Coated with a thin layer of lubricant, the brass can be formatted. Dies are used for this purpose, designed to give the shell a standard shape along the entire length (full sizing die) or only in the neck area (neck sizing die). The die is placed in the press, and the shell is attached to the press piston with a special holder.

The last stage of preparation is the insertion of new primers. This is done in the press, if allowed, or in a handheld priming tool.

Step 3 in reloading: powder weighing

This is a stage whose importance does not need to be emphasized. Traditionally, powder is measured first by volume from a dispenser or directly from a container using a powder measure. The load is placed on a small pan, which is placed on a scale (mechanical with a balance beam or an electronic one). The basic unit of measurement used in reloading is grain [gr], which corresponds to 0.065g in the metric system. Only scales with an accuracy of less than 0.2 gr are suitable for reloading. A roughly weighed sample, if it is smaller than intended, is supplemented with a microdoser (trickler), which allows feeding even single grains. If it is larger, unnecessary grains can be removed with tweezers. Recently, devices that automate the process and independently weigh and dispense the right amount of powder are becoming more and more popular, leaving the man only to pour it into the shell.

Step 4 in reloading: bullet seating

The powder-filled case is returned to the holder in the press. However, the die is changed from sizing to a seating die. It is necessary to properly determine the depth of seating the bullet in the neck of the case. Careless execution of this procedure can result in misalignment of the projectile. This usually leads to a deterioration in the accuracy of the ammunition.

It must be remembered that the unification of cartridges at any stage is, next to safety, the most important priority of the reloader. By itself, it still does not guarantee perfect grouping, but without it - excellent results can be forgotten.

Once is not enough

After completing all the carefully carried out activities, the handloader will be in possession of new, shiny and possibly identical cartridges, which will be used for experiments at the shooting range, hunting or finally in the case of the biggest aficionados (maniacs) - as a great source of shells for the next reloading...

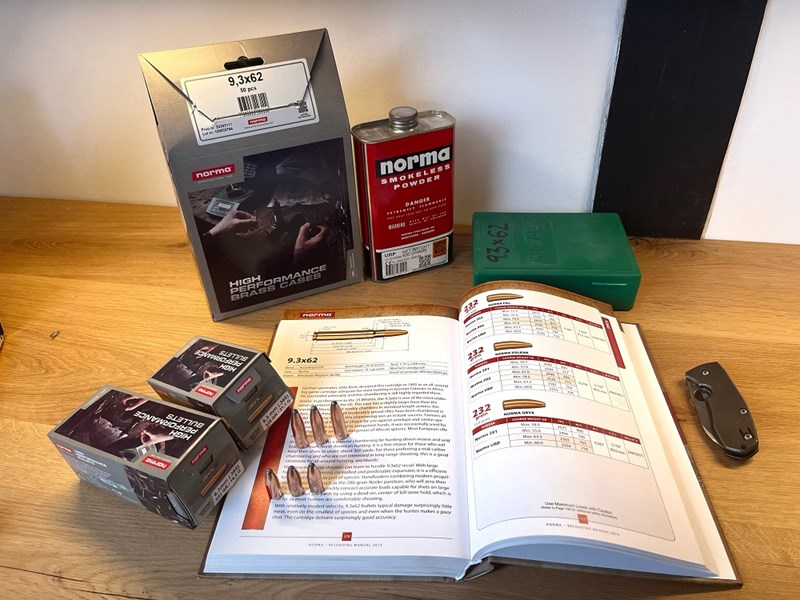

The concept: choosing the right bullet for the purpose and finding the appropriate powder charge using the manufacturers data

The concept: choosing the right bullet for the purpose and finding the appropriate powder charge using the manufacturers data Depriming old brass before cleaning

Depriming old brass before cleaning

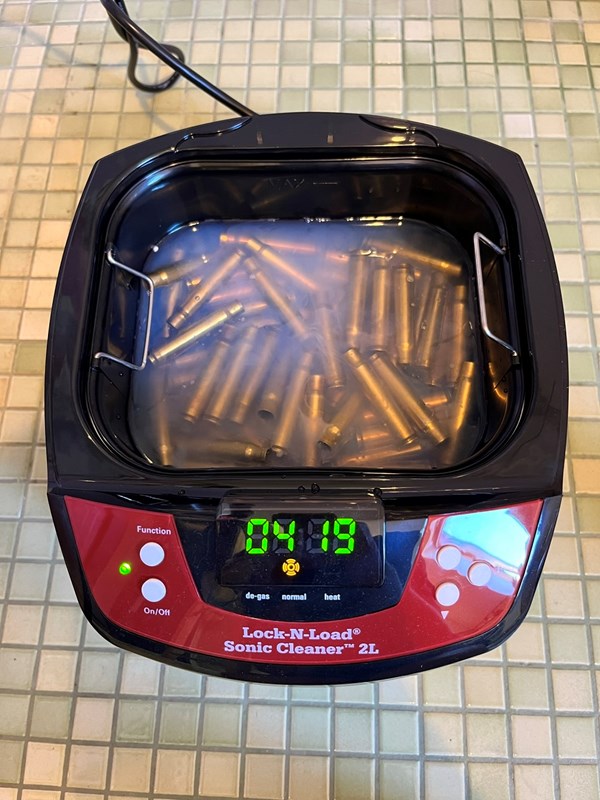

Cleaning the brass in a supersonic cleaner

Brass sizing

Powder weighing

Bullet seating